Introduction

In the drilling industry, safety should never be an afterthought — it must be part of every decision, from planning to execution. Whether working on water wells, mineral exploration, or civil groundwork, comprehensive safety practices prevent accidents, protect workers, and ensure project continuity.

Understanding Drilling Risks

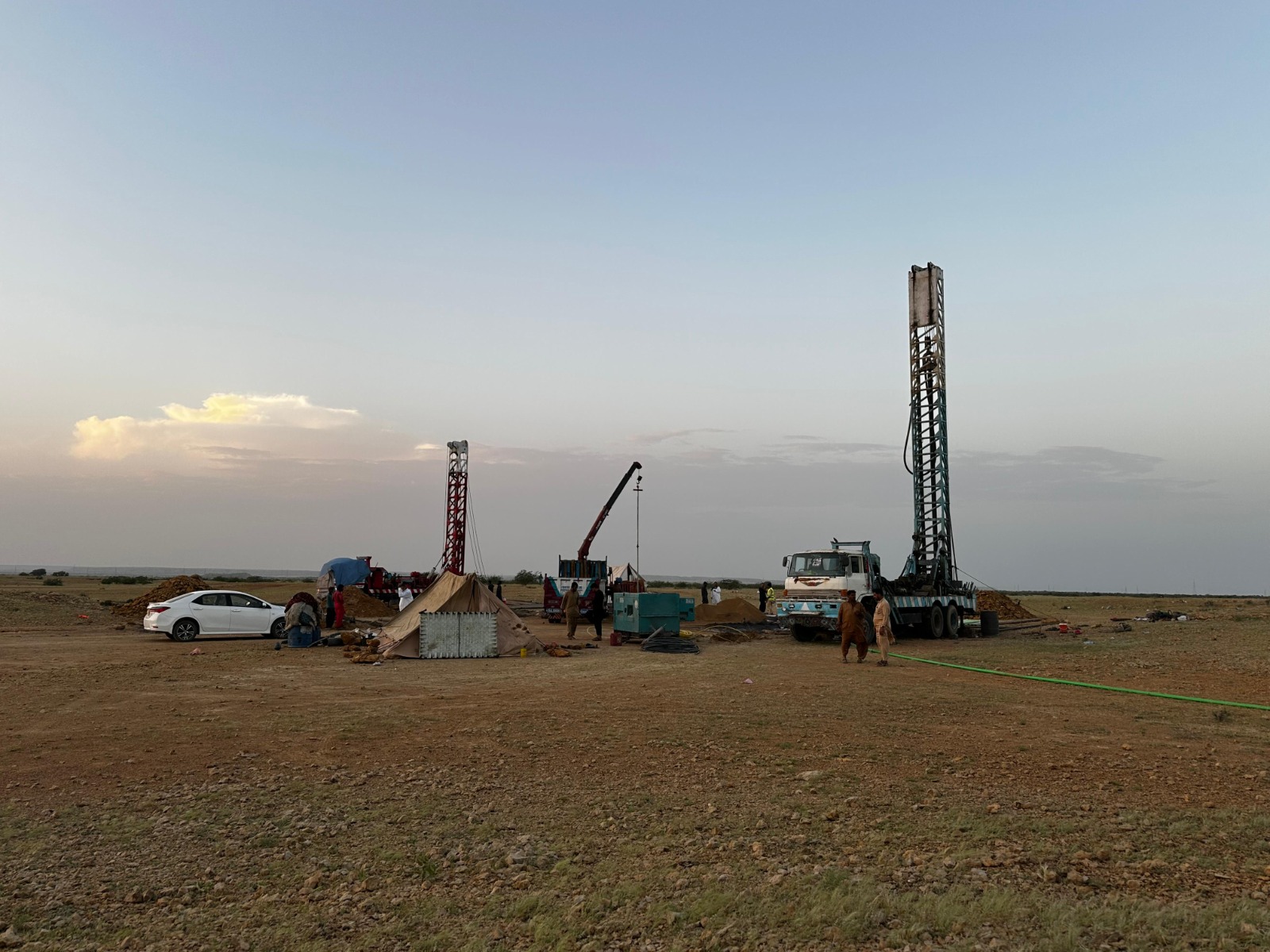

Drilling operations involve heavy equipment, deep holes, and complex machinery — all of which pose potential hazards such as equipment failure, falling objects, slips, and exposure to harmful materials. These risks highlight the importance of rigorous safety protocols before and during work.

What Makes an Effective Safety Culture?

A strong safety culture is built on:

1. Leadership Commitment: The top management must reinforce safety as an organizational priority.

2. Worker Engagement: Every worker should understand their role in maintaining safety and feel empowered to speak up when they identify risks.

3. Training & Education: Continuous training ensures personnel understand equipment, job hazards, and emergency procedures.

4. Clear Protocols: Standardized safety procedures streamline operations and reduce confusion when hazards arise.

Key Elements of Drilling Safety

Risk Assessment: A thorough evaluation of potential job hazards helps identify what could go wrong and how to prevent it.

Pre-Job Planning: Meetings before the start of drilling allow teams to discuss safety plans, roles, and emergency responses.

Equipment Safety: Regular equipment checks ensure tools and machines are in good working condition, reducing the chances of malfunctions.

Emergency Preparedness: Clear plans and accessible first-aid resources support rapid response in emergencies.

The Role of Continuous Improvement

Safety isn’t static — procedures must evolve with project scope, new technologies, and updated regulations. Companies that reassess safety practices continually are better equipped to protect their workers and reduce downtime.